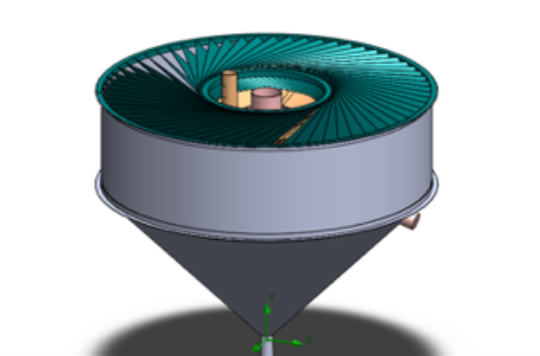

KraVi® De-Slimer

The KraVi® de-slimer is a washing device used to remove fine slimes, or fine light particles from larger or heavier particles in a metallurgical slurry. In most instances these fine particles comprise the clay mineral or fine silicate fraction. The KraVi® finds its application in any mineral slurry stream where there is a need to remove a problematic fine clay/silicate particle fraction in order to improve the metallurgical efficiency of a secondary upgrading or recovery process.